When a roller chain is employed, shaft positions could be arbitrarily established. Even so, in principle, observe the illustration shown beneath. That is certainly, if your chain is tensioned horizontally, hold the leading tensioned. Keep away from vertical transmission  when feasible. In an inevitable situation, spot the big sprocket with the bottom regardless of the direction of rotation.

when feasible. In an inevitable situation, spot the big sprocket with the bottom regardless of the direction of rotation.

When the chain layout is undesirable:

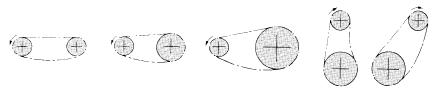

?Once the top rated is sagging as well as sprocket center distance is brief:

As illustrated under, alter the sprocket center distance shaft to eliminate the sag.

?When the top is sagging as well as sprocket center distance is lengthy:

As illustrated under, set up an idler from inside to reduce the sag.

?When the chain is vertical or inclined:

Eradicate the additional sag by a tensioner. In this case, a tensioner that automatically eliminates the sag provides improved outcomes.

Whenever a pulsating load acts in large speed operation:

The chain’s vibration along with the load effect frequency or chordal action may synchronize to amplify vibration to the chain. Since vibration has an effect on the chain, get countermeasures to stop vibration during the following measures:

?Change the chain speed.

?Boost chain tension. On the other hand, note that over-

tensioning can shorten the life on the chain. ?Use an idler or tensioner to divide the span

?Set up a manual stopper to stop vibration.

Note: Chordal action refers to your vertical motion of chain induced when it really is engaged with sprockets.

Industrial Chain

As one of leading industrial chain manufacturers, suppliers and exporters of mechanical products, We offer industrial chain and many other products.

Please contact us for details.

Manufacturer supplier exporter of industrial chain.

Recent Posts

- China Best Sales Qlv6112 Hv Rpv 12 3/2 Pitch 38.1 Centre Guide Steel Industrial Power Transmission Silent Chain

- China Custom 32A-2 160-2 ISO/DIN Drive Roller Chain Link Industrial Transmission Conveyor Chain

- China factory Stainless Steel Cast Drive Roller Pintle Conveyor Industrial Duplex Drag Link Engineering Chain Leaf Hollow Pin Elevator Silent Hoisting Agricultural Escalator

- China Hot selling Drive Roller Conveyor Leaf Hollow Pin Industrial Chain Elevator Silent Hoisting Pintle Cast Stainless Steel Duplex Engineering Drag Link Agricultural Escalator

- China Professional Carbon Steel/Stainless Steel Industrial Conveyor Roller Chain (08B 10B 12B 16B 40 50 60 80)

- China OEM Conveyor Transmission Motorcycle Industrial Carbon Stee Roller Chain Short Pitch Precision Stainless Steel Hollow Pin

- China Standard Short Pitch Precision stainless steel hardware Transmission Motorcycle Industrial Roller Chain

- China Best Sales Wholesale Factory Long Pitch Heavy Corn Wheat Rice Duty System C2050 C2060 Industrial Chain All Kinds of Transmission Chain Conveyor Chain Roller Chain

- China best 20A Chain Reliable and High Quality Stainless Roller Chain for Industrial

- China best 316 Stainless Steel Chain for Industrial Needs

- China Hot selling 3/4 Inch High Performance Lumbering None Standard Pitch 19.05 Stainless Steel Heavy Duty Industrial Chain Power Transmission Chain Roller Chain Conveyor Chain

- China Hot selling Factory Price OEM ODM Stainless Steel Material Carbon Steel Industrial Agriculture Roller Chain Hollow Pin Chain

- China high quality Drive Harvester Potting Motorcycle C/Ca Type Steel Industrial Agricultural Transmission Roller Chains

- China Professional 08B ISO Standard Stainless Steel Industrial Transmission Roller Chain with High Tensile Strength for Drving Machine

- China Good quality Transmission Conveyor Motorcycle/Timing /Bicycle Link Chain Roller Chain /Hollow Chain/ Industrial Steel Pintle Chain

- China Best Sales DIN Power Transmission Industry Carbon Steel Stainless Steel Heavy Duty a B Series Conveyor Chain for Industrial Applications Roller Chain 08b\10b\12b\16b

- China Hot selling Wholesale Factory Long Pitch Heavy Corn Wheat Rice Duty System C2050 C2060 Industrial Chain All Kinds of Transmission Chain Conveyor Chain Roller Chain

- China high quality China Hangzhou CZPT Heavy Duty Industrial Big Stainless Steel Link Chain

- China high quality New Pure Titanium Necklace Flat Long O-Chain European Hip Hop Fashion Couple Industrial Versatile Necklace Retro Silver Chain Tinl2383

- China supplier Engineering and Construction Machinery Industrial 64b-3 B Series Short Pitch Precision Triplex Industrial Martin Gearbox Roller Chains and Bush Chains

- China OEM Industrial Forging Chain with Machinery Parts and Roller

- China Best Sales Heavy Duty Galvanized Loading Anchor Chain for Industrial

- China best Conveyor Transmission Motorcycle Industrial Carbon Stee Roller Chain Short Pitch Precision Stainless Steel Hollow Pin

- China high quality G80L Heavy Duty Industrial Lifting Chain with Hook

- China Best Sales ISO16949: 2009 Approved Professional factory made industrial conveyor standard chain

- China supplier CZPT Stainless Steel Link Chain Heavy Duty Black Industrial Welded Chain

- China Best Sales Wholesale Factory C2050 C2060 Industrial All Kinds of Transmission Conveyor Roller Chain

- China factory 16b 25.4mm 16b-1 Ss16b-1 16bss 16b-2 16b-3 Factory Price Industrial Sprocket Drive Transmission Link Conveyor Roller Chain

- China manufacturer Factory Price OEM ODM Stainless Steel Material Carbon Steel Industrial Agriculture Roller Chain Hollow Pin Chain

- China Custom Transmission Industrial Conveyor Chain Roller Chain /Hollow Chain/Stainless Steel Pintle Chain/Motorcycle/Agricultural Chain

- China wholesaler Aluminium Chain for Jewelry Making Use for Necklace and Earrings CZPT Silver New in DIY Handcraft

- China Hot selling 1140A081 Timing Chain for L200 4n15 Engine Timing Repair Kit Timing Chain

- China Best Sales Standard or Non-Standard Industrial Transmission Chain for Sale

- China factory 32A-2 160-2 ISO/DIN Drive Roller Chain Link Industrial Transmission Conveyor Chain

- China Best Sales Stainless Steel Transmission Chain for Industrial Usage

- China wholesaler Economical Custom Design Industrial Double Pitch Conveyor Chain

- China Custom Best Price Excavator Parts Spare Parts Sk200-8 Track Chain Link Assy Track Chain

- China Good quality 08B ISO Standard Stainless Steel Industrial Transmission Roller Chain with High Tensile Strength for Drving Machine

- China factory Saw Engine Motorcycle Bicycle Sprocket Conveyor Driving Transmission Track Timing Roller Chain

- China Hot selling ISO16949: 2009 Approved Professional factory made industrial conveyor standard chain

- China best Engineering Class Roller C2082h Drag Conveyor Chain Lubricanttubular Industrial Transmission Conveyor Engineering Chain

- China supplier Simplex Roller Chain B Series Attachment Industrial Driving Transmission Chains

- China Professional Wholesale Price Power Transmission 08b Industrial Roller Chain with Extended Pins

- China wholesaler Industrial Free Flow Chain Roller Chain Speed Controllable Stainless Steel Conveyor Chain

- China high quality Factory Directly Wholesale Portable High Quality Industrial Conveyor Chains Attachment

- China best Hot Selling Industrial Standard Grip Chain for Transportation and Feeding

- China factory CZPT Industrial Forged Detachable Chain X348/X458 Conveyor Chain for Automotive

- China Best Sales CZPT Alloy Steel Heavy Duty Industrial Lifting Chain for Chain Block Load Chain

- China Professional British Standard Stainless Steel Roller Chain Industrial Manufacture Duplex Sharp Top Chain for Harvest Machine Chain

- China Professional Heavy Duty Industrial CZPT Znic Plated Welded Lift Chain

- China Good quality New Type Overhead Hanged Conveyor System Metal Chain for Industrial Powder Coating

- China high quality OEM Agricultural Machinery Engineering Industrial Transmission Conveyor Roller Chain

- China manufacturer Chinese Manufacturer of Industrial Lifting Chain with En818-2 Standard for Heavy Equipment Professional Factory Direct Sale

- China best DIN En 818-2 CZPT Lifting Alloy Steel Heavy Duty Industrial Lifting Chain Mine Link Chain DIN22252

- China Hot selling USA G70 Standard Nacm90/96 ASTM80 Tractor Heavy Yellow Chromate Iron Transport Tow Alloy Steel Industrial Chains with Hook

- China Standard DIN Power Transmission Industry Carbon Steel Stainless Steel Heavy Duty a B Series Conveyor Chain for Industrial Applications Roller Chain 08b\10b\12b\16b

- China Standard Power Transmission Industrial Large Rollers Large Size Conveyor Scrapper Dryer Double Side with Attachments Flaged Roller Chain

- China Standard Industrial Double Pitch Conveyor Roller Chain Conveyor Roller Chain

- China Professional Carbon Steel/Stainless Steel Industrial Conveyor Roller Chain (08B 10B 12B 16B 40 50 60 80)

- China Hot selling Factory Price OEM ODM Stainless Steel Material Carbon Steel Industrial Agriculture Roller Chain Hollow Pin Chain

- China wholesaler Transmission Conveyor Motorcycle/Timing /Bicycle Link Chain Roller Chain /Hollow Chain/ Industrial Steel Pintle Chain

- China Standard Candado Paso 40-1 Transmission Industrial Roller Chain 08A-1 08b-1 Cadena 25-1 04c-1 Chain 35-1

- China factory Industrial Drive Roller Conveyor Leaf Chain Hoisting Hollow Pin Heavy Duty Stainless Steel Short Double Pitch (AL BL LL)

- China factory Drive Roller Conveyor Leaf Hollow Pin Industrial Chain Elevator Silent Hoisting Pintle Cast Stainless Steel Duplex Engineering Drag Link Agricultural Escalator

- China Hot selling Saw Engine Motorcycle Bicycle Sprocket Conveyor Driving Transmission Track Timing Roller Chain

- China manufacturer Conveyor Transmission Motorcycle Industrial Carbon Stee Roller Chain Short Pitch Precision Stainless Steel Hollow Pin