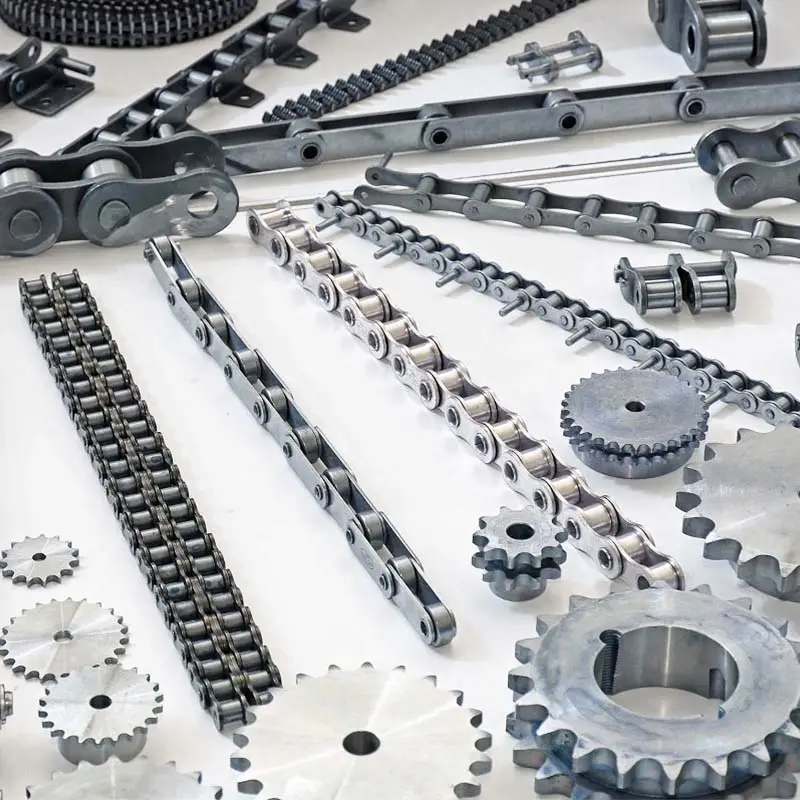

Product Description

Chinese Manufacturer of Industrial Lifting Chain with En818-2 Standard for Heavy Equipment Professional Factory Direct Sale

Attached is a form for your reference and we could produce any size based on your needs.

| (SIZE AND WEIGHT): | ||||||

| SIZE d*t MM | WIDTH b1 MIN b2MAX | WEIGHT KG/M | APPRAX LOAD KN | TEST LOAD KN | BREAKING LOAD MIN KN | |

| 6*8 | 7.5 | 21 | 0.79 | 1.1 | 27 | 45.2 |

| 7*21 | 9 | 24.5 | 1.07 | 1.5 | 37 | 61.6 |

| 8*24 | 10 | 28 | 1.38 | 2 | 48 | 80.4 |

| 10*30 | 12.5 | 35 | 2.2 | 3.2 | 76 | 125 |

| 11*43 | 12.6 | 36.5 | 2.33 | 3.8 | 92 | 154 |

| 12*36 | 15 | 42 | 3.1 | 4.6 | 109 | 181 |

| 13*39 | 16.3 | 46 | 3.8 | 5 | 128 | 213 |

| 14*42 | 18 | 49 | 4.13 | 6.3 | 150 | 250 |

| 15*46 | 20 | 52 | 5.17 | 7 | 168 | 280 |

| 16*48 | 20 | 56 | 5.63 | 8 | 192 | 320 |

| 18*54 | 23 | 63 | 6.85 | 10 | 246 | 410 |

| 19*57 | 23.7 | 63.2 | 7.7 | 11.3 | 270 | 450 |

| 20*60 | 25 | 70 | 8.6 | 12.5 | 300 | 500 |

| 22*66 | 28 | 77 | 10.7 | 15.3 | 366 | 610 |

| 23*69 | 29.9 | 85.1 | 10.2 | 16 | 415 | 665 |

| 24*72 | 32 | 82 | 12.78 | 18 | 432 | 720 |

| 25*75 | 32.5 | 92.5 | 14.1 | 20 | 491 | 785 |

| 26*78 | 35 | 91 | 14.87 | 21.3 | 510 | 850 |

| 28*84 | 36.4 | 104 | 17.6 | 25 | 616 | 985 |

| 30*90 | 38 | 105 | 19.6 | 28.3 | 678 | 1130 |

| 32*96 | 40 | 106 | 22.29 | 32.2 | 772 | 1286 |

| 36*108 | 46.8 | 133 | 29 | 40 | 1571 | 1630 |

| 40*120 | 52 | 148 | 36 | 50 | 1260 | 2571 |

| 45*135 | 58.5 | 167 | 45.5 | 63 | 1590 | 2540 |

| 48*144 | 60 | 170 | 52 | 72.5 | 1450 | 2900 |

Our Services

1. Prompt reply for inquiry within 24 hours

2. One on one service guarantees you the best purchasing experience.

3. Strong production capacity and professional technical engineer can gusrantee the delivery time and quality.

4. Strict quality control.

| Usage: | Transmission Chain, Drag Chain, Conveyor Chain, Dedicated Special Chain |

|---|---|

| Material: | Iron |

| Surface Treatment: | Electroplating |

| Feature: | Heat Resistant |

| Chain Size: | 1/2"*11/128" |

| Structure: | Welded Chain |

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning and alignment of an industrial chain drive?

Proper tensioning and alignment of an industrial chain drive are crucial for optimal performance, efficiency, and longevity of the system. Here are the steps to ensure correct tensioning and alignment:

- Tensioning:

1. Determine the manufacturer’s recommended tension for the specific industrial chain being used. This information can usually be found in the chain drive system documentation or provided by the manufacturer.

2. Measure the current tension of the chain using a tension measuring tool or gauge. This is typically done by applying a known force to a specific point on the chain and measuring the elongation or deflection.

3. Compare the measured tension with the recommended tension. If the measured tension is lower, the chain needs to be tensioned, while if it is higher, the tension needs to be reduced.

4. Adjust the tension by either increasing or decreasing the slack in the chain. This is usually done by adjusting the position of the chain tensioner or by altering the position of the chain drive components, such as the motor or sprockets.

5. Repeat the tension measurement and adjustment process until the recommended tension is achieved. It is important to ensure the tension is evenly distributed across the chain.

- Alignment:

1. Check the alignment of the chain drive components, including the motor, sprockets, and shafts. Misalignment can cause excessive wear, noise, and reduced efficiency.

2. Use alignment tools, such as laser alignment devices or straight edges, to assess the alignment of the components. The goal is to ensure that the chain runs parallel to the sprockets and that the sprockets are properly aligned with each other.

3. Make adjustments to correct any misalignment. This may involve shimming or repositioning the components to achieve proper alignment.

4. Verify the alignment by observing the chain’s movement and its interaction with the sprockets during operation. The chain should run smoothly without excessive vibration, noise, or rubbing against the sprocket teeth.

5. Regularly monitor the tension and alignment of the industrial chain drive and make necessary adjustments as part of the routine maintenance program.

Proper tensioning and alignment help minimize chain wear, reduce the risk of premature failure, and ensure smooth and efficient operation of the industrial chain drive system.

What are the industry standards and regulations for industrial chains?

There are several industry standards and regulations that govern the design, manufacturing, and use of industrial chains. These standards ensure safety, reliability, and performance consistency across different applications. Here are some prominent standards and regulations related to industrial chains:

– ISO 606: This standard specifies the design and dimensions of metric series roller chains used in industrial applications. It provides guidelines for chain pitch, roller diameter, and plate dimensions.

– ANSI/ASME B29.1: This American National Standard covers the design, dimensions, and interchangeability requirements for roller chains, including single, multiple, and double-pitch chains.

– ISO 10823: This standard focuses on the measurement and assessment of chain elongation during operation. It provides guidelines for evaluating the wear and elongation of roller chains.

– OSHA (Occupational Safety and Health Administration): OSHA sets safety standards and regulations to ensure a safe working environment. While it doesn’t specifically address industrial chains, it covers general machine guarding requirements that are applicable to chain-driven machinery.

– Machinery Directive (2006/42/EC): This European directive outlines the essential health and safety requirements for machinery and equipment. It covers aspects such as design, construction, and use of machinery, including industrial chains.

It’s important for manufacturers and users of industrial chains to be aware of these standards and regulations and ensure compliance. Adhering to these standards helps ensure the safety, reliability, and proper functioning of industrial chain systems in various industries.

What industries rely heavily on industrial chains?

Industrial chains play a critical role in various industries where the efficient movement of materials and products is essential. Here are some industries that heavily rely on industrial chains:

- Automotive industry: Industrial chains are used in automotive assembly lines for conveying and transferring components, as well as in engine systems for power transmission.

- Food and beverage industry: Industrial chains are widely used in food processing and packaging applications, such as conveying products, sorting, bottling, and canning.

- Mining industry: Industrial chains are utilized in mining equipment and conveyors for transporting ores, minerals, and bulk materials in harsh and demanding environments.

- Construction industry: Industrial chains are employed in construction machinery, such as cranes and excavators, for lifting heavy loads and facilitating construction operations.

- Agricultural industry: Industrial chains are essential in agricultural machinery, including tractors, combines, and harvesters, for power transmission and operating various components.

- Material handling industry: Industrial chains are widely used in material handling systems, such as conveyors, elevators, and warehouse automation, for efficient movement and sorting of goods.

- Paper and printing industry: Industrial chains are used in printing presses, bindery equipment, and paper manufacturing machines for paper handling and conveying.

- Chemical industry: Industrial chains are employed in chemical processing equipment, including mixers, reactors, and dryers, for material handling and process operations.

- Power generation industry: Industrial chains are used in power generation systems, such as steam turbines and generators, for transmitting power and controlling rotational movements.

- Textile industry: Industrial chains are utilized in textile machinery, such as weaving looms and spinning machines, for yarn movement and fabric production.

These are just a few examples, and industrial chains are found in numerous other industries where they enable efficient and reliable material handling, power transmission, and machine operation.

editor by CX 2023-11-07