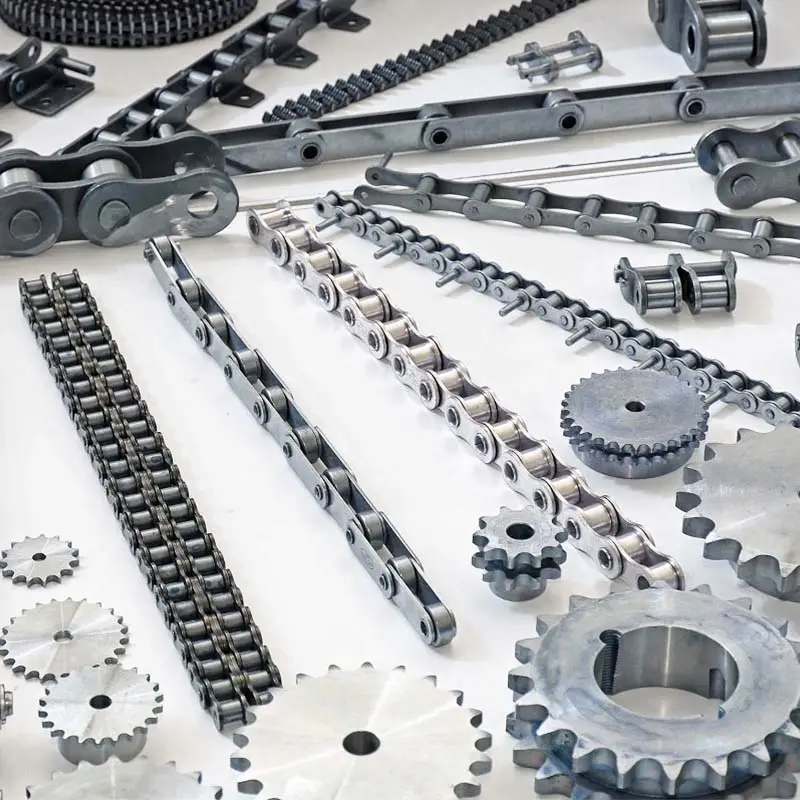

Product Description

G80 Chain Lifting Chain

1.Grade: CHINAMFG high tensile alloy steel chains for chain block, lever block, electric hoist.

2.Surface treatment: Self color, blackened, painted, electro galvanized, hot dip galvanized, painted etc.

3.Material: 20Mn2, 20Mnv (alloy steel chains, mild steel chains, welded lashing chains, transport chains, lifting chains, load chains)

4.Breaking load: we promise you that the tensile load reach up to Grade 80 level.

|

G80 LIFTING CHAIN |

|||||||||||||

| ITEM NO. | SIZE DXP(MM) | WIDTH(MM) | APPROX WEIGHT(KG/M) | WORKING LOAD LIMIT(T) | TEST LOAD(T) | BREAKING LOAD MIN.(KN) | |||||||

| INSIDE MIN. | OUTSIDE MAX. | ||||||||||||

| GL571-01 | 6×18 | 7.5 | 21 | 0.79 | 1.1 | 27 | 45.2 | ||||||

| GL571-02 | 7×21 | 9 | 24.5 | 1.07 | 1.5 | 37 | 61.6 | ||||||

| GL571-03 | 8×24 | 10 | 28 | 1.38 | 2 | 48 | 80.4 | ||||||

| GL571-04 | 10×30 | 12.5 | 35 | 2.2 | 3.2 | 76 | 125 | ||||||

| GL571-05 | 13×39 | 16.3 | 46 | 3.8 | 5 | 128 | 214 | ||||||

| GL571-06 | 16×48 | 20 | 56 | 5.63 | 8 | 192 | 320 | ||||||

| GL571-07 | 20×60 | 25 | 70 | 8.6 | 12.5 | 300 | 500 | ||||||

| GL571-08 | 22×66 | 28 | 77 | 10.2 | 15.3 | 366 | 610 | ||||||

| GL571-09 | 26×78 | 35 | 91 | 14.87 | 21.3 | 510 | 850 | ||||||

| GL571-10 | 32×96 | 40 | 106 | 22.29 | 32.2 | 772 | 1286 |

||||||

Payment

| Payment term | L/C | l/c amount above 40.000 usd,we can accept L/C at sight | |

| T/T |

EXW | 30% T/T in advance,paid the balance before shipment |

|

| FOB | |||

| CIF | 30% T/T in advance,paid the balance against copy of B/L |

||

| cfr(c&f) | |||

| paypal | amount lower than 4000usd |

||

| west | |||

| Delivery time | 15~35days after receiving payment for 1 container |

| We welcome use trade assurance,you`ll enjoy: 100% product quality protection 100% on-time shipment protection 100% payment protection for your covered amount |

| Usage: | Transmission Chain, Drag Chain, Conveyor Chain |

|---|---|

| Material: | Stainless steel |

| Surface Treatment: | Electroplating |

| Feature: | Fire Resistant |

| Chain Size: | 7mm |

| Structure: | Welded Chain |

| Customization: |

Available

| Customized Request |

|---|

What are the factors to consider when selecting the pitch of an industrial chain?

The pitch of an industrial chain refers to the distance between adjacent pins or rollers on the chain. When selecting the pitch of an industrial chain, several factors should be considered:

- Load requirements: The pitch of the chain should be selected based on the expected load that the chain will need to carry. Higher loads typically require larger pitch sizes to ensure sufficient strength and durability.

- Speed of operation: The chain’s pitch should be chosen based on the speed at which the chain will be operating. Higher speeds may require smaller pitch sizes to maintain smooth and efficient operation.

- Space limitations: The available space for the chain system should be considered when selecting the pitch. Smaller pitch sizes can accommodate tighter spaces, while larger pitch sizes may be suitable for applications with more ample space.

- Application requirements: The specific requirements of the application should be taken into account. Factors such as the type of load being transported, the operating environment (temperature, moisture, etc.), and any special considerations (e.g., noise reduction, corrosion resistance) can influence the pitch selection.

- Chain compatibility: It is essential to ensure that the selected chain pitch is compatible with the sprockets or gears used in the system. The chain and sprocket/gear pitch should match to ensure proper engagement and efficient power transmission.

- Service life expectations: Consideration should be given to the desired service life of the chain. In applications with high-cycle operations or demanding conditions, selecting a chain with a smaller pitch size or a specialized design may be necessary to enhance longevity.

By carefully considering the load requirements, speed of operation, space limitations, application requirements, chain compatibility, and service life expectations, one can select the appropriate pitch size for an industrial chain that ensures optimal performance and reliability.

Can an industrial chain be used for vertical lifting applications?

Yes, industrial chains can be used for vertical lifting applications. However, several factors need to be considered to ensure safe and efficient lifting operations:

- Chain type and strength: The industrial chain selected for vertical lifting applications must have the appropriate strength and load capacity to safely lift the intended load.

- Safety factors: It is crucial to consider the safety factors and ensure that the selected chain is capable of handling the maximum expected load without exceeding its rated capacity.

- Overhead clearance: Sufficient overhead clearance is necessary to accommodate the length of the chain and prevent any obstructions during the lifting process.

- Proper tensioning: The chain must be properly tensioned to prevent slippage or excessive slack, which can compromise the lifting operation.

- Guidance and control: Proper guidance and control mechanisms should be in place to ensure smooth and controlled vertical movement of the load.

- Maintenance and inspection: Regular maintenance and inspection of the chain are essential to identify any signs of wear, damage, or fatigue that may compromise its integrity and lifting capability.

It is important to consult industry standards, regulations, and specific manufacturer guidelines to determine the suitability of an industrial chain for a vertical lifting application. Additionally, working with experienced professionals and following established safety protocols is crucial to ensure the safe and effective use of the industrial chain in lifting operations.

How do you troubleshoot common issues with industrial chains?

Troubleshooting common issues with industrial chains involves identifying the problem, determining its cause, and taking appropriate corrective actions. Here are some common issues and troubleshooting steps:

- Chain misalignment: If the chain is misaligned, it can cause excessive wear, noise, and tension issues. To troubleshoot this, visually inspect the chain’s alignment and check if the sprockets are properly aligned. Adjust the sprockets and ensure they are aligned with the chain’s centerline.

- Chain elongation: Over time, industrial chains can elongate, leading to poor performance and increased stress on the components. To troubleshoot elongation, measure the chain’s pitch and compare it to the manufacturer’s specifications. If the chain is elongated beyond the recommended limit, it may need to be replaced.

- Inadequate lubrication: Insufficient or improper lubrication can result in increased friction and wear. Check the lubrication system and ensure the chain is properly lubricated according to the manufacturer’s recommendations. Adjust the lubrication schedule or consider using a different lubricant if necessary.

- Excessive chain tension: Excessive tension can cause increased wear, noise, and strain on the chain and components. Check the tension of the chain and adjust it to the manufacturer’s recommended specifications. Ensure proper tensioning devices, such as tensioners or idler sprockets, are in place and functioning correctly.

- Broken or damaged links: If there are broken or damaged links in the chain, they can cause performance issues and potential failure. Inspect the chain for any visible damage, such as broken pins or links, and replace the affected components as necessary.

- Excessive chain wear: Excessive wear can lead to chain elongation, decreased performance, and increased risk of failure. Regularly inspect the chain for signs of wear, such as elongation, worn sprocket teeth, or excessive clearance between the chain and sprockets. Replace the chain if it has reached its wear limit.

It is important to consult the manufacturer’s guidelines and recommendations for troubleshooting specific issues with the particular type of industrial chain being used. Additionally, regular maintenance, including proper lubrication, tensioning, and periodic inspections, can help prevent common issues and prolong the lifespan of the industrial chain.

editor by CX 2023-11-08