Product Description

Product Description

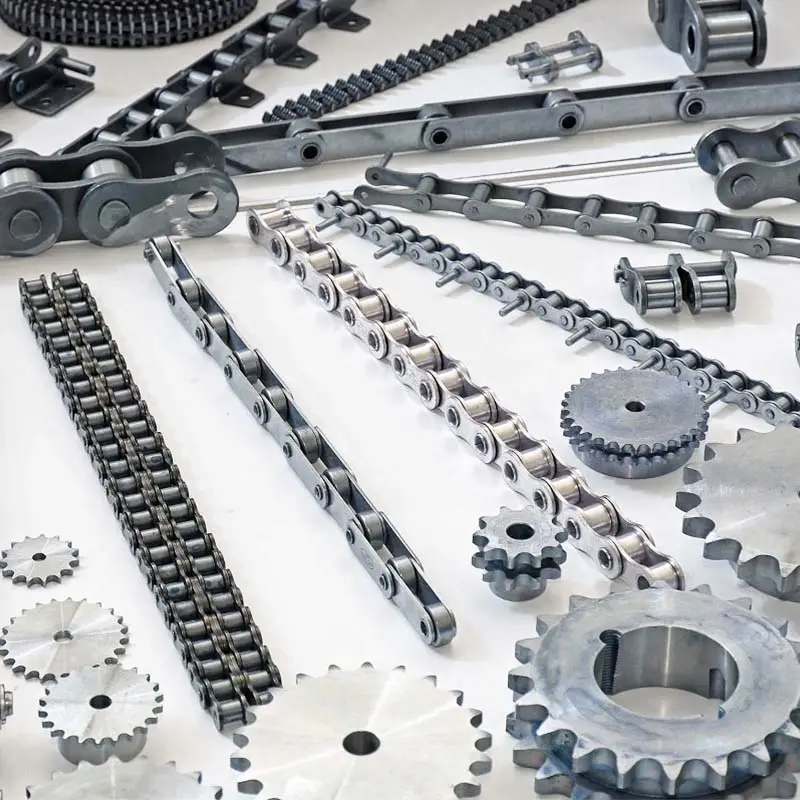

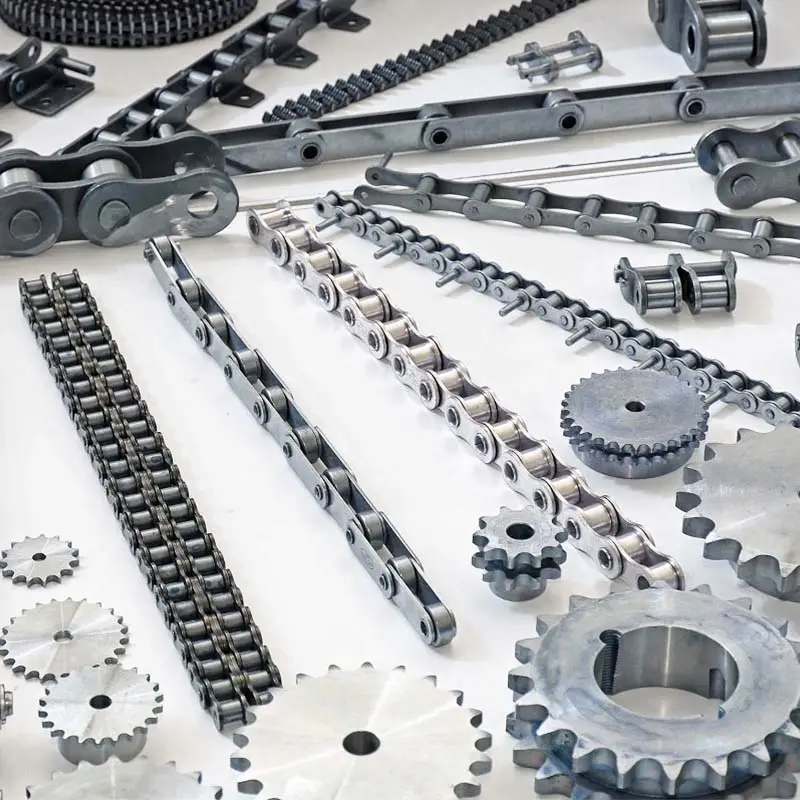

Vision Group is 1 of the largest manufacturers of Driving Chain, Conveyor Chain, Motorcycle Chain, Hoisting Chain, Agriculture Chain, Stainless Steel Chain, Dropped Forged Rivetless Chain, Long Pitch Conveyor Chain and so on.

GB/T, DIN, ANSI, ISO, BS, JIS.

ISO9001: 2000 and ISO1400: 2004.

Product Attribute

| Product name | Transmission Standard Roller Chain |

|

Surface Treatment |

Shot Peening ,Tempering Oiling ,Nickel-plated Grease, zince plated, Heat Treatment ,Stain proofing Carburizing ,Pre-stretched and anti-fatigue ,Quenching |

| Product application | Industry machine,Agriculture, mining, metallurgy, petrochemical industry, lifting and transportation and other industries |

| Product Series |

Series A, Series B, Heavy Duty |

| material |

Stainless steel and carbon steel |

| structure |

Simplex/Duplex/Triplex |

| Port |

Any sea port or airport in China |

| Brand | TV OEM |

| Payment |

L/C, T/T, D/P, Western Union |

| Package |

Chain, Plastic Bag, Color Box, Wooden Case. or OEM |

| A Series | 03C,04C-1,06C-1,085-1,08A-1,10A-1,12A-1,16A-1,20A-1,24A-1,28A-1,32A-1,36A-1,40A-1,48A-1.

15,25,35,41,40,50,60,80,100,120,140,160,180,200,240 |

| 04C-2,06C-2,085-2,08A-2,10A-2,12A-2,16A-2,20A-2,24A-2,28A-2,32A-2,36A-2,40A-2,48A-2.

25-2,35-2,41-2,40-2,50-2,60-2,80-2,100-2,120-2,140-2,160-2,180-2,200-2,240-2. |

|

| 04C-3,06C-3,085-3,08A-3,10A-3,12A-3,16A-3,20A-3,24A-3,28A-3,32A-3,36A-3,40A-3,48A-3.

25-3,35-3,41-3,40-3,50-3,60-3,80-3,100-3,120-3,140-3,160-3,180-3,200-3,240-3. |

|

| B Series | 05B-1,06B-1,08B-1,10B-1,12B-1,16B-1,20B-1,24B-1,28B-1,32B-1,40B-1,48B-1,56B-1,64B-1,72B-1. |

| 05B-2,06B-2,08B-2,10B-2,12B-2,16B-2,20B-2,24B-2,28B-2,32B-2,40B-2,48B-2,56B-2,64B-2,72B-2. |

|

| 05B-3,06B-3,08B-3,10B-3,12B-3,16B-3,20B-3,24B-3,28B-3,32B-3,40B-3,48B-3,56B-3,64B-3,72B-3. |

|

| Heavy Duty | 08AH-1,10AH-1,12AH-1,16AH-1,20AH-1,24AH-1,28AH-1,32AH-1,36AH-1,40AH-1,48AH-1

35H,40H,50H,60H,80H,100H,120H,140H,160H,180H,200H,240H |

| 12AH-2,16AH-2,20AH-2,24AH-2,28AH-2,32AH-2,40AH-2,

35H-2,40H-2,50H-2,60H-2,80H-2,100H-2,120H-2,140H-2,160H-2,180H-2,200H-2,240H-2. |

|

| 12AH-3,16AH-3,20AH-3,24AH-3,28AH-3,32AH-3,40AH-3

35H-3,40H-3,50H-3,60H-3,80H-3,100H-3,120H-3,140H-3,160H-3,180H-3,200H-3,240H-3. |

|

| Double pitch Series |

208A,208B,210A,210B,212A,212B,216A,216AH,216B,220A,220B,224A,224B,228B,232B

2040,2050,2060,2080,2080H,2100,2120 |

| We also carry out OEM according to your requirements | |

Product Parameters

Our Advantages

Company advantages:

Own Import & Export License, The TV trade mark registered successfully in many countries, Sales network spread all over China, Products export to 65 countries in 5 continents.

Membership:

1. The member of China General Machine Components Industry Association.

2. The member of China Chain Transmission Association.

3. The member of China Chain Standardization Association.

4. The member of China Agricultural Association Machinery Manufacturers.

With our excellent trained staffs and workers, advanced and efficient equipments, completely sales network, strict QA systems. You are confidence that our premium qualified chain can meet all customers’ specification and strictest quality standards.

WHY CHOOSE US

Comprehensive Product Portfolio We produce and supply a wide range of power transmission

products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and

couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while

guarantee youfind what you want at 1 click.

Value Choice Products Our products are the best combination of quality and price, and you get what

you want within your budgets

Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers;

on our team at your disposal any time when you need a helping hand. They are well trained with industry

know-now and will always respond to your requests within 24 hours.

100% Customer Retention Rate Our regular customers from overseas come back not just for our

premium quality products, but for the superior services that we’ve provided over the years.

FAQ

Q1: What’s your average lead time?

A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate.

Q2: Is your price better than your competitors given the same quality?

A: Definitely YES. We provide the most competitive price in the power transmission industry. If price disparity exists, we’ll be more than happy to do a price match.

Q3: Can you make chains according to my CAD drawings?

A: Yes. Besides the regular standard chains, we produce non-standard and custom-design products to meet the specific technical requirements. In reality, a sizable portion of our production capacity is assigned to make non-standard products.

Q4: Can we inspect the goods before shipment?

A: Yes. You or your representative or any third-party inspection party assigned is allowed access to our facility and do the inspection.

Q5: What kind of payment method is acceptable for your mill?

A: We’re flexible. We take T/T, L/C, or any other online payment methods so long as it’s applicable for you.

Q6: What if I have any other questions?

A: Whenever in doubt, you’re always encouraged to consult our sales associate any time – They will help you to your satisfaction.

| Usage: | Transmission Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Polishing |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the factors to consider when selecting the pitch of an industrial chain?

The pitch of an industrial chain refers to the distance between adjacent pins or rollers on the chain. When selecting the pitch of an industrial chain, several factors should be considered:

- Load requirements: The pitch of the chain should be selected based on the expected load that the chain will need to carry. Higher loads typically require larger pitch sizes to ensure sufficient strength and durability.

- Speed of operation: The chain’s pitch should be chosen based on the speed at which the chain will be operating. Higher speeds may require smaller pitch sizes to maintain smooth and efficient operation.

- Space limitations: The available space for the chain system should be considered when selecting the pitch. Smaller pitch sizes can accommodate tighter spaces, while larger pitch sizes may be suitable for applications with more ample space.

- Application requirements: The specific requirements of the application should be taken into account. Factors such as the type of load being transported, the operating environment (temperature, moisture, etc.), and any special considerations (e.g., noise reduction, corrosion resistance) can influence the pitch selection.

- Chain compatibility: It is essential to ensure that the selected chain pitch is compatible with the sprockets or gears used in the system. The chain and sprocket/gear pitch should match to ensure proper engagement and efficient power transmission.

- Service life expectations: Consideration should be given to the desired service life of the chain. In applications with high-cycle operations or demanding conditions, selecting a chain with a smaller pitch size or a specialized design may be necessary to enhance longevity.

By carefully considering the load requirements, speed of operation, space limitations, application requirements, chain compatibility, and service life expectations, one can select the appropriate pitch size for an industrial chain that ensures optimal performance and reliability.

How does an industrial chain compare to other types of power transmission systems?

An industrial chain is a type of power transmission system that offers several advantages compared to other systems:

- Strength and durability: Industrial chains are designed to handle heavy loads and withstand tough operating conditions. They are known for their high strength and durability, making them suitable for demanding industrial applications.

- Efficiency: Industrial chains provide efficient power transmission, minimizing energy loss during operation. They offer high mechanical efficiency, which is especially important in applications that require precise and consistent power transfer.

- Flexibility: Industrial chains are flexible in terms of design and configuration. They can be easily adapted to various applications and can transmit power over long distances, making them suitable for a wide range of industrial machinery and equipment.

- Cost-effectiveness: Industrial chains are often cost-effective compared to alternative power transmission systems. They are relatively simple in design, easy to manufacture, and have a lower initial cost. Additionally, their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings.

- Reliability: Industrial chains are known for their reliability and consistent performance. When properly maintained and operated within their load and speed limits, they can provide reliable power transmission for extended periods.

- Versatility: Industrial chains can accommodate various environmental conditions, including high temperatures, corrosive environments, and high-speed applications. They can be made from different materials and configured with specific features to suit specific application requirements.

While industrial chains offer numerous advantages, it is essential to consider specific application needs and requirements when selecting a power transmission system. Factors such as load capacity, operating environment, speed, and precision may influence the suitability of an industrial chain compared to alternatives such as belts, gears, or shafts.

Can an industrial chain be repaired or does it need to be replaced entirely?

Whether an industrial chain can be repaired or needs to be replaced entirely depends on the extent of damage and the type of chain. In some cases, minor issues with an industrial chain can be repaired, while in other cases, replacement may be necessary. Here are some considerations:

- Extent of damage: If the chain has minor issues such as a damaged link or a loose pin, it may be possible to repair it by replacing the damaged component. However, if the chain has significant damage, such as severe elongation or multiple broken links, it may be more cost-effective to replace the entire chain.

- Type of chain: The repairability of an industrial chain also depends on its construction and design. Some chains, such as roller chains, can be disassembled and repaired by replacing individual components. However, other types of chains, such as welded steel chains, may be difficult or impractical to repair and may require complete replacement.

- Manufacturer’s recommendations: It is essential to consult the manufacturer’s guidelines and recommendations regarding repairs. The manufacturer can provide specific information on whether the chain can be repaired and the proper procedures to follow.

- Cost and time considerations: Repairing an industrial chain may require specialized tools, replacement parts, and technical expertise. It is important to consider the cost of repairs, including labor and materials, compared to the cost of a new chain. Additionally, repair time should be taken into account, as it may result in downtime for the equipment or production line.

Ultimately, the decision to repair or replace an industrial chain should be based on factors such as the extent of damage, the chain’s design, manufacturer’s recommendations, and cost-effectiveness. It is recommended to consult with a qualified technician or contact the manufacturer for guidance in making this determination.

editor by CX 2023-11-06