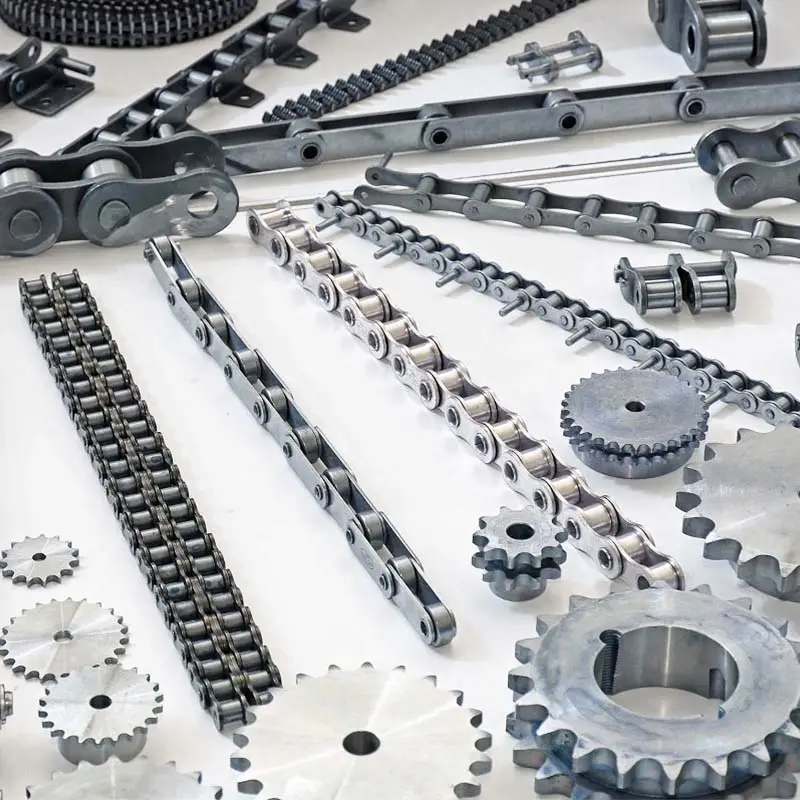

Product Description

Short Pitch Precision Roller Chains

A. Our Services:

1. Any of your kind inquiry about chain would be replied within 24 hours.

2. Well-trained and experienced sales staffs will reply all your concerns in fluent English.

3. OEM services are available with us, our professional designer would make your private idea into being.

4. Protection of your sales area, ideas of design and all your private information.

5. Delivery by air mail or ship for your orders.

6. With years of manufacture and promotion experience in global market, brings you profit and great success!

B.Product Description:

| Style: | Simplex Roller Chains, Duplex Roller Chains, Triplex Roller Chains, Multiple Roller Chains |

| Chain No.: (ANSI/ISO) | 03C, 04C, 06C, 08A, 10A, 12A-~ 48A |

| Chain No.: ( ANSI ) | 15, 25,35,41,40,50 ~ 240 |

| Pitch: | 4.7625 mm ~ 76.200 mm |

C.Company show & Product Process

D. Packaging & Certificate

| Packaging Details: | Chain+Plastic Bag+Neutral Box+Wooden case+Big Carton+Steel Pallets |

| Delivery Detail: | five weeks |

E. FAQ:

1. Are you manufacturer or trade Company?

We are a factory founded in 1991 with trade team for international service.

2. What terms of payment you usually use?

T/T 30% deposit and 70% against document, Western Union, L/C at sight

3. what is your lead time for your goods?

Normally 45 days after confirmed order. 30 days could be available in low season for some items (during May to July), and 65 days during new year and hot season ( Jan to March).

4. Do you attend any Show?

We attend Hannover show in Germany, NMW in Austrilia, Canton fair, PTC, in China and many other special furniture shows.

5. Do you have any instant chat ?

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Usage: | Conveyor Chain |

|---|---|

| Material: | Alloy/Carbon Steel |

| Surface Treatment: | Electroplating |

| Feature: | Heat Resistant |

| Chain Size: | 1/2"*11/128" |

| Structure: | Roller Chain |

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning and alignment of an industrial chain drive?

Proper tensioning and alignment of an industrial chain drive are crucial for optimal performance, efficiency, and longevity of the system. Here are the steps to ensure correct tensioning and alignment:

- Tensioning:

1. Determine the manufacturer’s recommended tension for the specific industrial chain being used. This information can usually be found in the chain drive system documentation or provided by the manufacturer.

2. Measure the current tension of the chain using a tension measuring tool or gauge. This is typically done by applying a known force to a specific point on the chain and measuring the elongation or deflection.

3. Compare the measured tension with the recommended tension. If the measured tension is lower, the chain needs to be tensioned, while if it is higher, the tension needs to be reduced.

4. Adjust the tension by either increasing or decreasing the slack in the chain. This is usually done by adjusting the position of the chain tensioner or by altering the position of the chain drive components, such as the motor or sprockets.

5. Repeat the tension measurement and adjustment process until the recommended tension is achieved. It is important to ensure the tension is evenly distributed across the chain.

- Alignment:

1. Check the alignment of the chain drive components, including the motor, sprockets, and shafts. Misalignment can cause excessive wear, noise, and reduced efficiency.

2. Use alignment tools, such as laser alignment devices or straight edges, to assess the alignment of the components. The goal is to ensure that the chain runs parallel to the sprockets and that the sprockets are properly aligned with each other.

3. Make adjustments to correct any misalignment. This may involve shimming or repositioning the components to achieve proper alignment.

4. Verify the alignment by observing the chain’s movement and its interaction with the sprockets during operation. The chain should run smoothly without excessive vibration, noise, or rubbing against the sprocket teeth.

5. Regularly monitor the tension and alignment of the industrial chain drive and make necessary adjustments as part of the routine maintenance program.

Proper tensioning and alignment help minimize chain wear, reduce the risk of premature failure, and ensure smooth and efficient operation of the industrial chain drive system.

Can an industrial chain be used for vertical lifting applications?

Yes, industrial chains can be used for vertical lifting applications. However, several factors need to be considered to ensure safe and efficient lifting operations:

- Chain type and strength: The industrial chain selected for vertical lifting applications must have the appropriate strength and load capacity to safely lift the intended load.

- Safety factors: It is crucial to consider the safety factors and ensure that the selected chain is capable of handling the maximum expected load without exceeding its rated capacity.

- Overhead clearance: Sufficient overhead clearance is necessary to accommodate the length of the chain and prevent any obstructions during the lifting process.

- Proper tensioning: The chain must be properly tensioned to prevent slippage or excessive slack, which can compromise the lifting operation.

- Guidance and control: Proper guidance and control mechanisms should be in place to ensure smooth and controlled vertical movement of the load.

- Maintenance and inspection: Regular maintenance and inspection of the chain are essential to identify any signs of wear, damage, or fatigue that may compromise its integrity and lifting capability.

It is important to consult industry standards, regulations, and specific manufacturer guidelines to determine the suitability of an industrial chain for a vertical lifting application. Additionally, working with experienced professionals and following established safety protocols is crucial to ensure the safe and effective use of the industrial chain in lifting operations.

What industries rely heavily on industrial chains?

Industrial chains play a critical role in various industries where the efficient movement of materials and products is essential. Here are some industries that heavily rely on industrial chains:

- Automotive industry: Industrial chains are used in automotive assembly lines for conveying and transferring components, as well as in engine systems for power transmission.

- Food and beverage industry: Industrial chains are widely used in food processing and packaging applications, such as conveying products, sorting, bottling, and canning.

- Mining industry: Industrial chains are utilized in mining equipment and conveyors for transporting ores, minerals, and bulk materials in harsh and demanding environments.

- Construction industry: Industrial chains are employed in construction machinery, such as cranes and excavators, for lifting heavy loads and facilitating construction operations.

- Agricultural industry: Industrial chains are essential in agricultural machinery, including tractors, combines, and harvesters, for power transmission and operating various components.

- Material handling industry: Industrial chains are widely used in material handling systems, such as conveyors, elevators, and warehouse automation, for efficient movement and sorting of goods.

- Paper and printing industry: Industrial chains are used in printing presses, bindery equipment, and paper manufacturing machines for paper handling and conveying.

- Chemical industry: Industrial chains are employed in chemical processing equipment, including mixers, reactors, and dryers, for material handling and process operations.

- Power generation industry: Industrial chains are used in power generation systems, such as steam turbines and generators, for transmitting power and controlling rotational movements.

- Textile industry: Industrial chains are utilized in textile machinery, such as weaving looms and spinning machines, for yarn movement and fabric production.

These are just a few examples, and industrial chains are found in numerous other industries where they enable efficient and reliable material handling, power transmission, and machine operation.

editor by CX 2024-01-08