With single spur gears, a couple of gears forms a gear stage. If you connect several gear pairs one after another, that is known as a multi-stage gearbox. For each gear stage, the path of rotation between the drive shaft and the output shaft is reversed. The overall multiplication aspect of multi-stage gearboxes is certainly calculated by multiplying the ratio of each gear stage.

The drive speed is reduced or increased by the factor of the apparatus ratio, depending on whether it’s a ratio to sluggish or a ratio to fast. In nearly all applications ratio to sluggish is required, because the drive torque is multiplied by the overall multiplication factor, unlike the drive speed.

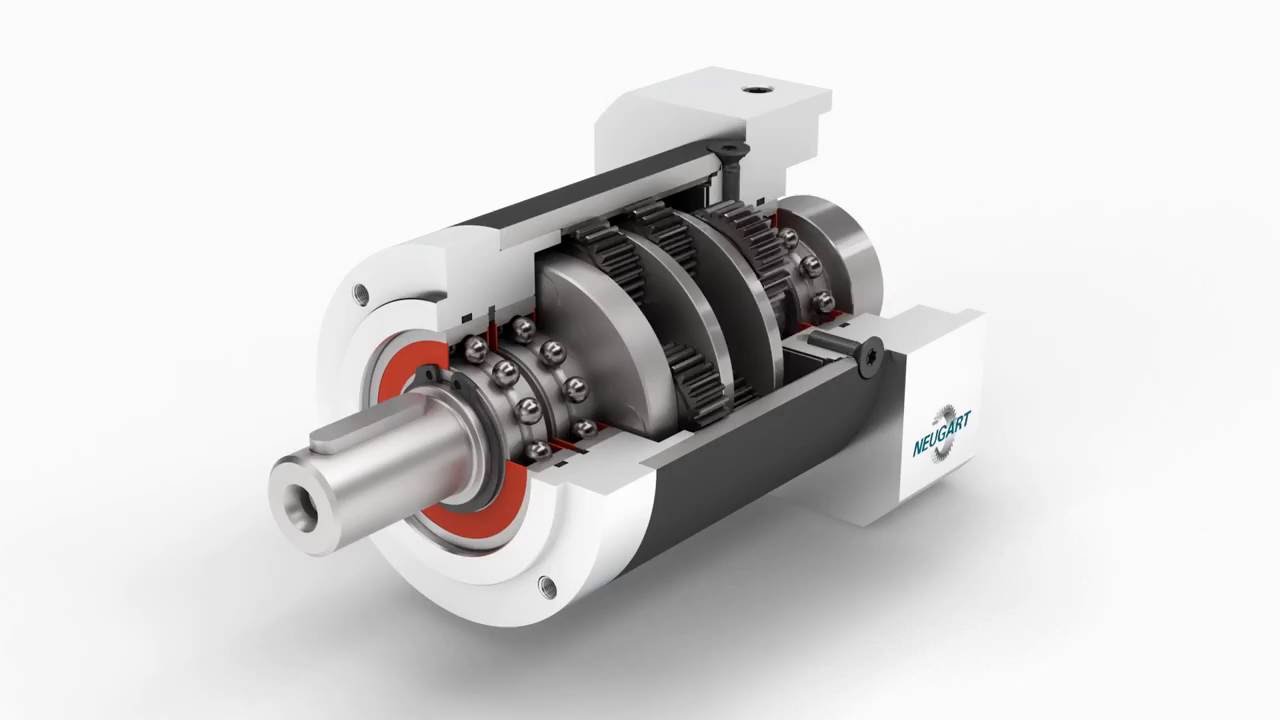

A multi-stage spur gear could be realized in a technically meaningful way up to a gear ratio of around 10:1. The reason for this is based on the ratio of the amount of tooth. From a ratio of 10:1 the generating gearwheel is extremely small. This has a negative influence on the tooth geometry and the torque that’s getting transmitted. With planetary gears a multi-stage gearbox is extremely easy to realize.

A two-stage gearbox or a three-stage gearbox may be accomplished by just increasing the distance of the ring gear and with serial arrangement of a number of multi stage planetary gearbox individual planet levels. A planetary equipment with a ratio of 20:1 could be manufactured from the individual ratios of 5:1 and 4:1, for example. Instead of the drive shaft the planetary carrier contains the sun gear, which drives the following world stage. A three-stage gearbox is obtained through increasing the length of the ring equipment and adding another planet stage. A transmission ratio of 100:1 is obtained using individual ratios of 5:1,  5:1 and 4:1. Basically, all individual ratios could be combined, which results in a sizable number of ratio choices for multi-stage planetary gearboxes. The transmittable torque can be increased using additional planetary gears when performing this. The direction of rotation of the drive shaft and the output shaft is often the same, so long as the ring gear or housing is fixed.

5:1 and 4:1. Basically, all individual ratios could be combined, which results in a sizable number of ratio choices for multi-stage planetary gearboxes. The transmittable torque can be increased using additional planetary gears when performing this. The direction of rotation of the drive shaft and the output shaft is often the same, so long as the ring gear or housing is fixed.

As the number of equipment stages increases, the efficiency of the overall gearbox is decreased. With a ratio of 100:1 the efficiency is lower than with a ratio of 20:1. To be able to counteract this situation, the fact that the power loss of the drive stage can be low must be taken into concern when using multi-stage gearboxes. That is attained by reducing gearbox seal friction reduction or having a drive stage that is geometrically smaller, for instance. This also decreases the mass inertia, which is certainly advantageous in dynamic applications. Single-stage planetary gearboxes are the most efficient.

Multi-stage gearboxes can also be realized by combining various kinds of teeth. With the right angle gearbox a bevel gear and a planetary gearbox are simply combined. Here as well the overall multiplication factor is the product of the average person ratios. Depending on the type of gearing and the type of bevel equipment stage, the drive and the output can rotate in the same path.

Benefits of multi-stage gearboxes:

Wide variety of ratios

Constant concentricity with planetary gears

Compact design with high transmission ratios

Combination of different gearbox types possible

Wide range of uses

Disadvantages of multi-stage gearboxes (in comparison to single-stage gearboxes):

More complex design

Lower degree of efficiency

The automatic transmission system is quite crucial for the high-speed vehicles, where in fact the planetary or epicyclic gearbox is a typical feature. With the upsurge in style intricacies of planetary gearbox, mathematical modelling has become complex in nature and for that reason there is a need for modelling of multistage planetary gearbox like the shifting scheme. A random search-centered synthesis of three examples of freedom (DOF) high-acceleration planetary gearbox provides been presented in this paper, which derives an efficient gear shifting system through designing the tranny schematic of eight velocity gearboxes compounded with four planetary equipment sets. Furthermore, with the help of lever analogy, the transmission power movement and relative power efficiency have been established to analyse the gearbox design. A simulation-based tests and validation have already been performed which show the proposed model can be effective and produces satisfactory change quality through better torque features while shifting the gears. A new heuristic solution to determine suitable compounding arrangement, based on mechanism enumeration, for creating a gearbox layout is proposed here.

Multi-stage planetary gears are widely used in many applications such as for example automobiles, helicopters and tunneling boring machine (TBM) because of their advantages of high power density and huge reduction in a small volume [1]. The vibration and noise problems of multi-stage planetary gears are generally the focus of attention by both academics and engineers [2].

The vibration of simple, single-stage planetary gears has been studied by many researchers. In the early literatures [3-5], the vibration structure of some example planetary gears are identified using lumped-parameter models, however they didn’t provide general conclusions. Lin and Parker [6-7] formally discovered and proved the vibration framework of planetary gears with equal/unequal planet spacing. They analytically categorized all planetary gears settings into exactly three groups, rotational, translational, and world settings. Parker [8] also investigated the clustering phenomenon of the three setting types. In the latest literatures, the systematic classification of settings had been carried into systems modeled with an elastic continuum ring equipment [9], helical planetary gears [10], herringbone planetary gears [11], and high rate gears with gyroscopic effects [12].

The organic frequencies and vibration settings of multi-stage planetary gears have also received attention. Kahraman [13] set up a family group of torsional dynamics models for compound planetary gears under different kinematic configurations. Kiracofe [14] developed a dynamic style of compound planetary gears of general description including translational examples of freedom, which allows an infinite number of kinematic combinations. They mathematically proved that the modal characteristics of substance planetary gears were analogous to a straightforward, single-stage planetary gear system. Meanwhile, there are various researchers focusing on the nonlinear dynamic features of the multi-stage planetary gears for engineering applications, such as for example TBM [15] and wind mill [16].

According to the aforementioned versions and vibration structure of planetary gears, many researchers concerned the sensitivity of the natural frequencies and vibration modes to system parameters. They investigated the result of modal parameters such as tooth mesh stiffness, planet bearing stiffness and support stiffness on planetary gear natural frequencies and vibration settings [17-19]. Parker et al. [20-21] mathematically analyzed the consequences of design parameters on natural frequencies and vibration modes both for the single-stage and compound planetary gears. They proposed closed-type expressions for the eigensensitivities to model parameter variants according to the well-defined vibration mode properties, and set up the relation of eigensensitivities and modal energies. Lin and Parker [22] investigated the veering of planetary gear eigenvalues. They utilized the structured vibration modes showing that eigenvalue loci of different setting types always cross and those of the same setting type veer as a model parameter is certainly varied.

However, most of the existing studies only referenced the technique used for single-stage planetary gears to analyze the modal features of multi-stage planetary gears, as the differences between these two types of planetary gears were ignored. Due to the multiple degrees of freedom in multi-stage planetary gears, more detailed division of organic frequencies are required to analyze the influence of different system parameters. The objective of this paper is certainly to propose an innovative way of analyzing the coupled settings in multi-stage planetary gears to investigate the parameter sensitivities. Purely rotational degree of freedom models are accustomed to simplify the analytical investigation of gear vibration while keeping the primary dynamic behavior generated by tooth mesh forces. In this paper, sensitivity of natural frequencies and vibration modes to both gear parameters and coupling shaft parameters of multi-stage planetary gears are studied.

1. Planetary gear sets can be found in wide reduction gear ratios

2. Gear set can combine the same or different ratios

3. Planetary gear set is available in plastic, sintered metallic, and steel, depending on different application

4. Hight efficiency: 98% efficiency at single decrease, 95% at double reduction

5. Planetary gear arranged torque range: Low torque, middle torque, high torque

6. Easy linking with couplings, input shafts, result shafts

The planetary gear is a special type of gear drive, where the multiple world gears revolve around a centrally arranged sunlight gear. The planet gears are installed on a planet carrier and engage positively within an internally toothed ring gear. Torque and power are distributed among many planet gears. Sun equipment, planet carrier and band gear may either be driving, driven or fixed. Planetary gears are used in automotive building and shipbuilding, as well as for stationary make use of in turbines and general mechanical engineering.

The GL 212 unit allows the investigation of the dynamic behaviour of a two-stage planetary gear. The trainer contains two planet gear sets, each with three world gears. The ring gear of the first stage is usually coupled to the planet carrier of the next stage. By fixing individual gears, you’ll be able to configure a complete of four different tranny ratios. The gear is accelerated with a cable drum and a variable set of weights. The group of weights is elevated via a crank. A ratchet helps prevent the weight from accidentally escaping. A clamping roller freewheel enables free further rotation following the weight offers been released. The weight is certainly caught by a shock absorber. A transparent protective cover helps prevent accidental connection with the rotating parts.

To be able to determine the effective torques, the force measurement measures the deflection of bending beams. Inductive speed sensors on all drive gears permit the speeds to become measured. The measured values are transmitted directly to a Personal computer via USB. The info acquisition software is roofed. The angular acceleration can be read from the diagrams. Effective mass occasions of inertia are dependant on the angular acceleration.

investigation of the powerful behaviour of a 2-stage planetary gear

three planet gears per stage

four different transmission ratios possible

gear is accelerated via cable drum and variable set of weights

weight raised yourself crank; ratchet prevents accidental release

clamping roller freewheel allows free further rotation after the weight has been released

shock absorber for weight

transparent protective cover

pressure measurement on different gear levels via 3 bending bars, display via dial gauges

inductive speed sensors

GUNT software for data acquisition via USB below Windows 7, 8.1, 10

Technical data

2-stage planetary gear

module: 2mm

sun gears: 24-tooth, d-pitch circle: 48mm

planet gears: 24-tooth, d-pitch circle: 48mm

band gears: 72-tooth, d-pitch circle: 144mm

Drive

set of weights: 5…50kg

max. potential energy: 245,3Nm

Load at standstill

weight forces: 5…70N

Measuring ranges

speed: 0…2000min-1

230V, 50Hz, 1 phase

230V, 60Hz, 1 stage; 120V, 60Hz, 1 phase

UL/CSA optional

he most basic type of planetary gearing involves three sets of gears with different examples of freedom. World gears rotate around axes that revolve around a sun gear, which spins in place. A ring gear binds the planets externally and is completely fixed. The concentricity of the planet grouping with sunlight and ring gears implies that the torque bears through a straight range. Many power trains are “comfortable” prearranged straight, and the absence of offset shafts not only reduces space, it eliminates the need to redirect the energy or relocate other elements.

In a simple planetary setup, input power turns sunlight gear at high swiftness. The planets, spaced around the central axis of rotation, mesh with the sun along with the fixed ring equipment, so they are forced to orbit as they roll. All of the planets are mounted to a single rotating member, known as a cage, arm, or carrier. As the planet carrier turns, it provides low-speed, high-torque output.

A fixed component isn’t constantly essential, though. In differential systems every member rotates. Planetary arrangements such as this accommodate a single output powered by two inputs, or an individual input generating two outputs. For instance, the differential that drives the axle in an vehicle is planetary bevel gearing – the wheel speeds represent two outputs, which must differ to handle corners. Bevel equipment planetary systems operate along the same principle as parallel-shaft systems.

Even a simple planetary gear train provides two inputs; an anchored ring gear represents a continuous input of zero angular velocity.

Designers can proceed deeper with this “planetary” theme. Compound (as opposed to simple) planetary trains have at least two world gears attached in line to the same shaft, rotating and orbiting at the same velocity while meshing with different gears. Compounded planets can possess different tooth numbers, as can the gears they mesh with. Having this kind of options significantly expands the mechanical opportunities, and allows more decrease per stage. Compound planetary trains can simply be configured therefore the world carrier shaft drives at high velocity, while the reduction problems from sunlight shaft, if the developer prefers this. One more thing about substance planetary systems: the planets can mesh with (and revolve around) both set and rotating external gears simultaneously, therefore a ring gear is not essential.

Planet gears, for their size, engage a whole lot of teeth because they circle the sun gear – therefore they can certainly accommodate many turns of the driver for each output shaft revolution. To execute a comparable reduction between a standard pinion and gear, a sizable gear will need to mesh with a rather small pinion.

Simple planetary gears generally provide reductions as high as 10:1. Compound planetary systems, which are more elaborate than the simple versions, can offer reductions many times higher. There are apparent ways to additional decrease (or as the case may be, increase) quickness, such as connecting planetary stages in series. The rotational output of the first stage is linked to the input of the next, and the multiple of the average person ratios represents the final reduction.

Another option is to introduce standard gear reducers into a planetary teach. For example, the high-rate power might pass through an ordinary fixedaxis pinion-and-gear set before the planetary reducer. This kind of a configuration, known as a hybrid, is sometimes preferred as a simplistic option to additional planetary stages, or to lower insight speeds that are too high for a few planetary units to take care of. It also provides an offset between the input and result. If the right angle is needed, bevel or hypoid gears are occasionally attached to an inline planetary program. Worm and planetary combinations are rare since the worm reducer alone delivers such high changes in speed.