Chain Variety

To absolutely exhibit its exceptional functions, a chain conveyor will have to match the application. Choose essentially the most ideal chain by accurately identifying the traits of your chain conveyor technique and support circumstances (forms and properties of your load, conveyance capability, speed, distance, service surroundings, and so forth.).

Refer for the choice flowchart below, as well as the information on each stage from the choice method.

Variety Flowchart

Although complete awareness and expertise are necessary for deciding on chains, a common selection procedure is described here to assist you in choosing the optimum conveyor chain.

Variety of Chain Pitch

Usually, a chain by using a smaller sized pitch travels additional smoothly and lasts longer as it receives less shock. Nevertheless, its larger variety of back links effects in an increase of the entire excess weight, diminishing cost efficiency. Conversely, a chain with a bigger pitch receives much more shock which shortens chain daily life and causes noise.

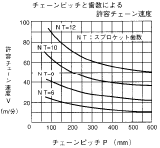

The chain pitch is made the decision by  thinking of the operation speed as well as the sprocket teeth amount.

thinking of the operation speed as well as the sprocket teeth amount.

Generally, make use of the chain at or lower compared to the allowable chain velocity shown during the graph around the right.

For Use in Dusty Surroundings

When using chains in an surroundings of dirt, sand, dust, and so on., periodically wash and lubricate the chain. For greasing, use a grease gun to permit the lubricant to sufficiently penetrate in to the clearances

involving pins and bushings, bushings and rollers, and outer plates and inner plates. When using chains inside a very abrasive surroundings, we propose the following:

1) Select a conveyor made to stop the chains from coming into get in touch with using the abrasive loads, or cover the chain.

two) Select a chain together with the greatest size feasible to reduce the face pressure of bearing portions such as between pins and bushings.

3) Keep the chain pace as low as possible.

4) Make grease holes inside the pins and bushings, and lubricate with grease nipples.

(Seek the advice of us when drilling pins and bushings as they are reinforced parts.)

For dusty environments and hugely abrasive environments, high dress in resistant bearings this kind of as chain, DJ, Diesten and Dimec bearings are available.